Post Background

We have been advising companies in the NDIS space regarding the quality of construction output and processes to help deliver better work to participants. Since starting this initiative, we have encountered several jobs that have left us perplexed. As you may know, there are significant issues in the NDIS sector, largely driven by greed and exploitation of opportunities. This has resulted in tradespeople performing exceptionally poor quality work on-site.

While tradespeople are ultimately responsible for the work, the businesses contracting them often lack an understanding of construction, construction management, or quality management, despite their best efforts to help participants.

The situation in NDIS work is challenging, so we must now focus on educating and informing people while creating simple yet effective systems of work. This ensures the best quality is delivered to those who rely on this work for basic access and mobility needs.

Currently, authorities and the system are outdated in their approach, relying on a "spray and pray" method and evaluating quotes solely on cost. The new home construction industry faces similar issues but is slightly more evolved in handling quality management. However, there is virtually no regulatory oversight in this sector, and the occupational therapists scoping the work are not qualified to design the projects they are quoting.

Without a proper process for designing, scoping, and managing the quality of jobs, we will remain stuck with poor quality projects being delivered to clients.

Rather than just being critical, we have detailed a process and timeline we believe will improve quality by attracting and compensating qualified individuals to design, detail job requirements, and assist with accurate quoting and contract documentation. (See below)

Background

- An email was received on Monday April 15th to review concrete works noting that the client had advised works performed did not meet the scope of work, and they had concerns about “cracking”.

Date of Assessment

- 17th April 2024

Scope of Quoted Work

- ###Building Co## Quote Job Number: 1569 + 1750

- Original Job Cost? - I am not sure if this is the sum of these two jobs or one/the other job amounts. This is unclear to me if the total job cost was:

- Cost A - $6613.90 (sum of Cost B + Cost C)

- Cost B - $3788.90 - Job 1750 Invoice

- Cost C - $2825 - Job 1569 Invoice

- The scope of work included on the quote includes:

- Supply and Install a 5.8m x 2m wide plain concrete path

- 100mm thick concrete

- Reinforced

- Broom Finished

- Spoil (excavated material) removed from site (skip bin)

As Constructed (photos)

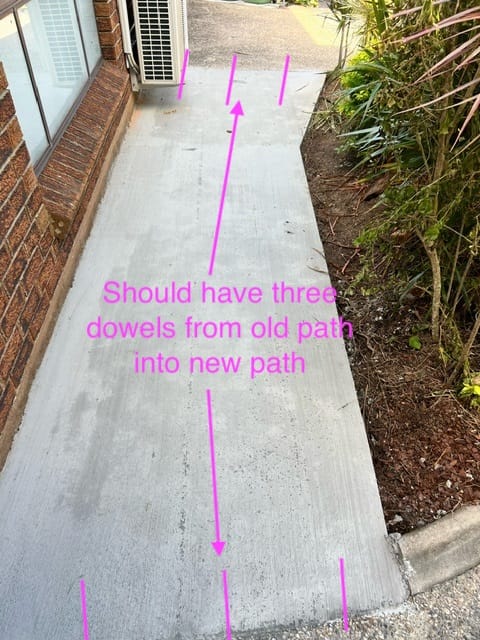

Photo 1

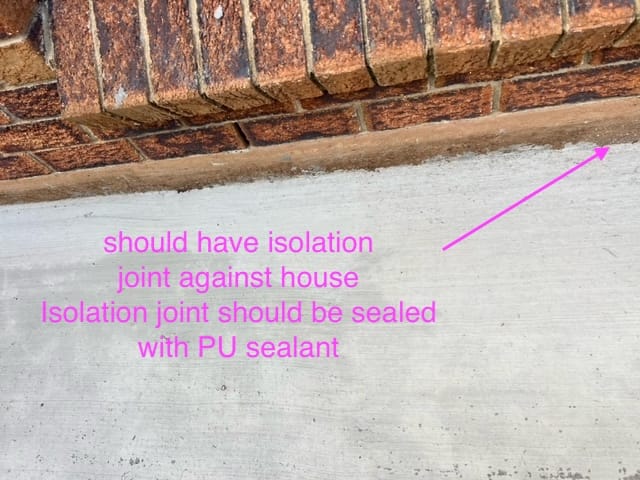

Photo 2

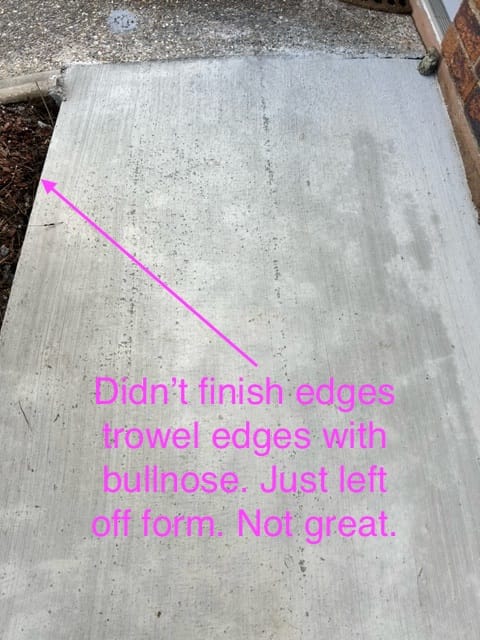

Photo 3

Photo 4

Photo 5

Photo 6

Photo 7

Photo 8

Photo 9

Job Assessment

- The concrete thickness was not installed as per the quote (100mm quoted).

- Almost no, to minimal/nominal subgrade preparation was done.

- Minimal removal of existing and almost no adequate subgrade establishment.

- No compacted road base, crusher dust or sand bed was installed.

- No plastic membrane was installed.

- Insufficient sized reinforcement used for crack control (SL52 looks to be what was installed from the supplied images)

- No bar chairs installed to reinforcement to give it correct cover within the concrete.

- Reinforcement not at correct cover can increase likelihood of cracking (reduce crack control)

- No dowelling, connection to existing concrete works to prevent differential movement between old concrete and new concrete

- Over time the new section of concrete may move independently of the old concrete meaning grinding of the lip page will be required to prevent a trip hazard.

- No edge finishing (bull nosing) to outside or inside edges of the concrete

- Just off form square edges with zero hand finishing was done.

- Edge finishing is required for appearance (aesthetics) and to provide adequate surfaces for the polyurethane sealant to bond to.

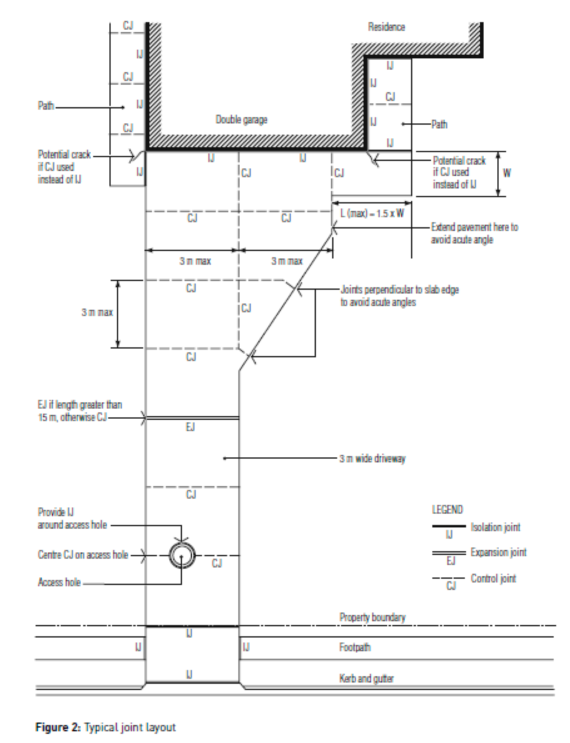

- No control, isolation or expansion joints have been installed —See Figure 2 below for typical joint locations.

- Should be at 1.8m to 2m maximum spacing down the length of the path.

- No isolation joints were installed

- To against the house slab/path joint

- To around the down pipe penetration

- No expansion joints were installed

- When the new path abuts the old path

- No polyurethane sealant was installed to isolation joints (not formed) next to house and around down pipe penetration point.

- PU Sealant prevents water and dirt getting between the house and the path or between joins in surfaces and reducing the likelihood of path movement (cracking and changes in surface levels).

- No finishing of the garden edge to pathway connection was done which has created a new trip/fall hazard for the home owner.

- Workers should have chamfered the garden edge to blend it down to the pathway grade

- No 1:20 falls away from house (50mm over the first 1000mm is required under the NCC for areas of intense rainfall (25mm for less intense rainfall)) and be at least 50mm below the finished surface of adjacent slabs.

- This should have been discussed with OT and the falls and transition agreed upon and signed off prior to commencement of work

- The current quote documentation/lack of specificity is leaving ## Builders exposed in terms of Clients saying “I thought I was getting X” because there wasn't enough degree of specificity or detail in the quote to begin with, and people will trust and agree with you until they understand exactly what is and is not included.

- This always ends up with the provider paying more to compensate or appease the builder and is often categorised as “marketing” expenses when it can easily be mitigated through better process and details.

- It's clear from the completed work that there was no job scope, quality management, trade inspection test or witness hold points (quality management) or even an understanding of the general requirements to comply with the NCC or applicable standards.

- There should have been a regulated contract in place between builder and client that detailed job scope and requirements/deliverables, time, costs and quality.

Figure 2

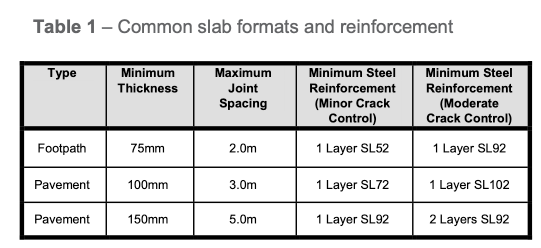

Table 1

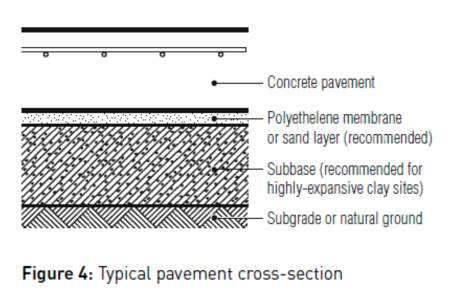

Figure 4

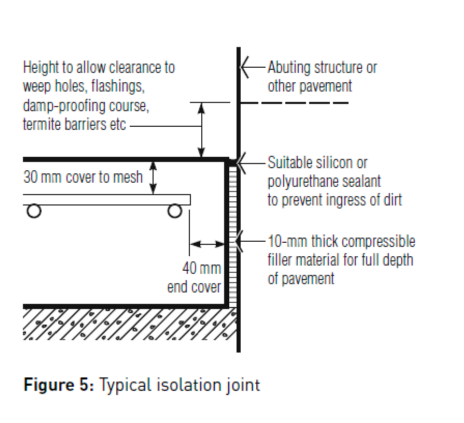

Figure 5

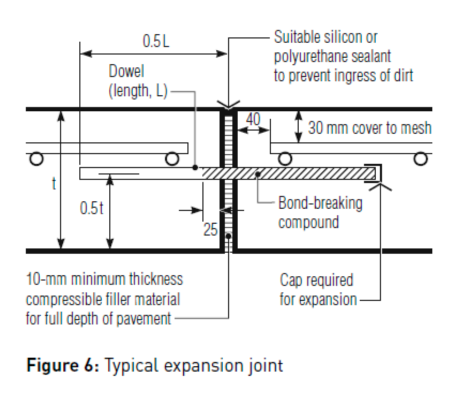

Figure 6

Recommendations

- Always use a contract, have supporting contract documents detailing the scope, cost and job details. It removes as much ambiguity as possible and provides both parties with "rules of engagement" - to a point.

- Always create/include a sketch or diagram with job quotes that details the size and shape, location, total m2 of works to be carried out and detail/note all other elements that are related to the works (falls, finishing, level, set downs, thickenings, control joint locations, isolation joints, expansion joint location).

- Job requirements/inclusions must be detailed so they are built into the works on site and not left up to chance. There was no quality control evident from the observed pictures.

- Be sure to detail a clear specification/inclusions so that there is a detailed job/site Chain of Custody available (if needed for auditing or compliance/dispute management or maintenance purposes).

- The specification should consider include and detail:

- The strength of concrete used. N20, 20MPA is the minimum and it must be higher if salts (salinity) or groundwater is present in the soil, then N25 minimum strength must be used.

- The thickness of the concrete must be detailed. Pathways for foot traffic must have a minimum thickness of 75mm. Pathways for vehicles less than 3T in gross mass should be 100mm minimum thickness (see Table 1).

- It is always best to install 100mm thick pathways given the nominal extra cost to do so over 75mm and the Public’s understanding of what “normal” is. They think 100mm is “normal” so its best to just price for and provide this and avoid discussion (arm chair experts).

- The size of reinforcement to be used, SL92/SL82 unless soil conditions onsite are known then use less grades (SL72, SL62).

- It would be difficult to know the soil conditions unless you get soil reports or soil type confirmation fro home owners - highly unlikely they will know or have this information - unless its a relatively new home (newly constructed).

- The area of the works broken down by locations - like “11.6m2 plain concrete pathway, broom finished to front elevation adjacent to front entry door.”

- Detail edge finishes, bull nose, off form, or a general “all edges finished with 12mm radius (approx) bull nose trowel”.

- The specification should consider include and detail:

- Detail the sub base/subgrade - understand that this depends on if the site is reactive or not, which you might not know, so its best to assume all sites are reactive and just do the same scope for each job. See Figure 4.

- Supply & Install A 100mm thick compacted (dampened and compacted) road base is the standard subgrade then, polyethylene film or 20mm of fine sand.

- Reinforcement must be placed on bar chairs 4 per m2 minimum or sufficient to support concrete pouring to ensure:

- 30mm top cover to mesh - (see Figure 5).

- 40mm end cover to mesh - (see Figure 5).

- Install 10mm minimum ableflex to existing concrete walls, around penetrations (downpipes).

- Install expansion joints where connecting into existing concrete surfaces using dowels to prevent new concrete from moving independently of old concrete and to ensure that concrete can move/expand/contract across the subgrade (it should slip which is why we use plastic or sand to facilitate slippage).

- Detail joints on site sketches nominating locations correctly, and installing per the Australian Standards:Figure 5: typical isolation joint.

- Remove topsoil, vegetation, debris and tree roots, foreign matter

- Consider that to increase crack control, higher strength reinforcement is required and must be placed at the correct depth in the concrete (not lifting mesh into position

- Apply 12mm deep (2:1 width to depth) polyurethane sealant to maximum 15 mm width (on top of 10 mm compressible filler) joints (ableflex) - mask/tape concrete edges, apply sealant, apply fine sand to wet sealant, remove excess sand (blower), remove tape, cleanup. See Figure 6: typical expansion joint

Repair Options

- OPTION 1 - As mentioned over the phone, but before I had seen the pre-pour images, an applied coating like CoverCrete ($55/m2) may have been a repair option.

- However, since seeing the photos, I do not believe that this is a good option for two reasons.

- Firstly, when making a concession like this (applying a coating) to rectify an issue, the Client will often want the remainder of adjacent concrete to match to rectification works, increasing the scope and cost of the repair.

- A partial solution (we will cover it up) is an admission of fault which can then be exploited or leveraged by the Client at your expense and you have no counter position.

- CoverCrete does not guarantee that the existing plain concrete won't crack nor the cracks migrate through to the covercrete layer, then requiring additional repair anytime a crack surfaces.

- Covercrete is strong but it is poor in tensile strength (like un-reinforced concrete) and will crack with subgrade movement.

- I would anticipate the subgrade (and new concrete path to move) once the surrounding are is fully saturated with rain.

- The Client sent through over 40 images to you. I do not believe they will accept an applied coating because a little trust has been eroded and everything other than a replacement will seem like “sub-solution”.

- However, since seeing the photos, I do not believe that this is a good option for two reasons.

- PREFERRED REPAIR - OPTION 2- Remove and redo the work incorporating best practices as we have detailed in this document below (see section 11 below, repair work cost plan).

Future Considerations

- A point to consider is that all of this type of work is essentially “insurance work” given that the NDIS is subsidising/paying for it.

- Insurance work always requires a higher degree of detail to ensure ts done to applicable standards.

- Given that it is insurance, and a national scheme, there may be a point in the future that site works are assessed and a NCR - Non Compliance Report is issued because work does not meet applicable standards.

- Insurance companies will often pay higher rates to have work completed, but this is not because they are nice, it's because all the work is 100% the responsibility of the contractor performing works and accepting insurance money.

- You should implement the recommendations of this document in all future concrete work to ensure you have adequately discharged your responsibilities under the NCC and the Australian Standard

Recommendations

- Ensure all job specifications, and the scope of work, is clear and well detailed and communicated to site staff through proper contracts and purchase orders.

- Ensure any OT specified details are checked for compliance with the NCC and referenced standards. OT’s are not trained in construction (general assumption) so everything they specify should be checked and discussed with them to ensure the best compliance before work commences.

- It is always the licensed professionals responsibility to ensure compliance with the construction code, standards and QDC (Queensland Development Code).

- I do understand that these jobs are often priced under $3300 to mitigate this, but as a company you will still bear the responsibility for the quality of the output work, and it may affect how you are perceived in the marketplace, your public image.

- Have quotes/contracts signed off by clients prior to work commencement.

- Includes more information in your quotes like:

- The strength of concrete used

- The size/type of reinforcement used

- A sketch of the job including dimensions and any job/finishing elements/treatments, joint locations/types.

- Subgrade details and preparation - inclusions.

- Includes more information in your quotes like:

- Ensure that site staff understand the scope of work that has been quoted and what is required to be installed on site compliance.

- Most likely the way they have always done it is not correct, unless they have taken the time to read and implement the Australian Standards through a Quality Management Plan or they have developed ITP - Inspection Test Plans for their specific trade.

- Implement a quality management process (witness/hold points) so it is not possible for site staff to ignore planning or quality control processes.

- Detail ITPs (part of a quality management system) for each trade performed, and ensure people performing a trade know and understand the ITP.

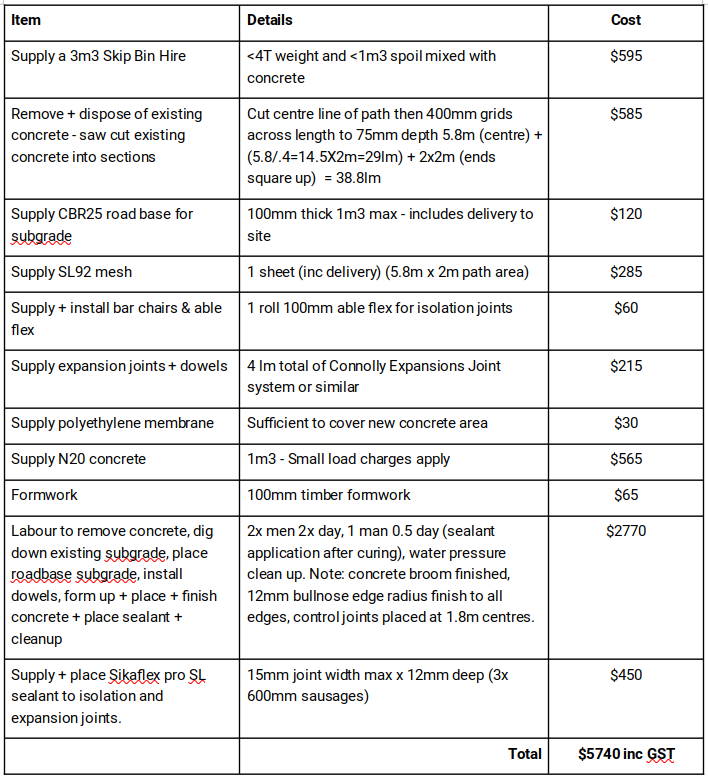

REPAIR OPTION 2 Cost Plan — 5.8m long x 2m wide broom finished, plain concrete path — 100 mm thick

References

- AS 1379 Manufacture and supply of concrete, Standards Australia, 2007

- AS 3600 Concrete structures, Standards Australia, 2009.

- Building Technology Resources: Foundation Maintenance and Footing Performance: Understanding and preventing soil related building movement, CSIRO (2021)

- Guide to Residential Slabs and Footings in Saline Environments (T56) Cement Concrete & Aggregates Australia, 2005.

- Permeable Concrete Pavements Data Sheet, Cement Concrete & Aggregates Australia, 2004.

- National Construction Code, Volume 2, Building Code of Australia, Australian Building Codes Board, 2016.

- The Concrete Masonry Association of Australia website (www.cmaa.com.au). Information on Concrete Segmental Pavements and Concrete Flag Pavements can be found under technical publications.

- AS2758.1 Aggregates and rock for engineering purposes: Part 1 – Concrete Aggregates.

Report Created & Compiled by: Anthony Painter