Introduction

If your thinking of getting into the construction industry or you're already a player, welcome one and all. What a fantastic choice you've made to be a part of one of the most dynamic and people-centric industries in Australia.

Like all markets where there is a low barrier to entry you may soon find that standing out from the crowd will be one of your biggest challenges. You are not alone. This is a challenge we all face, but I'm going to give you some insight and tools into how you can be better than your competition. Before we get into that, let's touch on why we're all here to begin with.

Why We're Here

The purpose of a company is to improve the quality of the customer’s life. The purpose of a company is to deliver value at a very high level to the customer. The purpose of a company is to strip away the non-value-added activity and deliver to the customer more value consistently day after day, month after month, year after year. When you do that, your stature increases in the eye of your customer, your customer keeps coming back for more and then you make more money.

The Three Main Areas of Focus

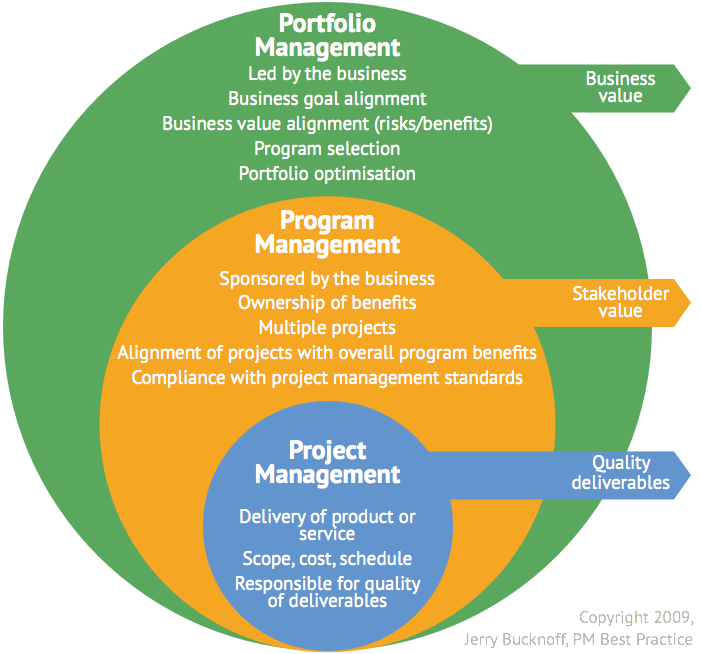

There are three main areas you need to focus on if you want to be better than your competition they are: purpose, people & process.

Purpose

Lean thinking is one of the simplest management principals to learn and understand that gives you the most dramatic effect to your bottom line over the shortest time frame. Like most newly acquired skills the real challenge is to maintain momentum and continue their application to your business.

People

The best way to foster people is to embrace lean methodologies in everything you do. What is lean? Lean is simply a process of constant improvement. Have you ever wondered how technology companies seem to be able to scale rapidly and take over a market (like Uber). They use the principals of lean to iterate rapidly and innovate their way through "the chasm" to find product/market fit. In summary, they are constantly improving themselves and their product, evolving to the markets needs.

Lean is not just something you do. Lean is a strategy built around a strong culture of Lean thinking that can effectively let value flow to the customer.

Process

How many builders do you know who's house design, materials or methodologies never change? Why not apply lean thinking to what you're doing now, today and stand out from your competition? Lean is simply eliminating waste or non-value-added activity. Anything that doesn’t add value to your customer is waste. The customer wants the product. They don’t want to have to pay for me to make it. Start by focussing on yourself and the problems you face on a daily basis. Can you make a small improvement in each step of what you do? I guarantee to you if you make a 1% daily improvement and maintain this process you will be doing more that 99% of your competition.

Embracing Lean Thinking

So how do you do this? Start by improving yourself first, lead by example. Don't try and force lean thinking on anyone. Just focus on you to start. Begin reading process management books (critical chain theory for one - thank you Eli Goldratt) to learn about bottlenecks, throughput & inventory. Up skill your strengths (forget about your weaknesses), through education (CSQ), attending workshops and seminars about how to build, manage your people, and refine your processes. Do this and you'll soon be in the 1%.

The Power of Lean Methodologies

Profit and money are a by-product of an effective lean culture. We are here first and foremost to improve the quality of the customer’s life. Internally, we are here to grow our people. If we do both of these at a high level, we will be profitable. Profit is not the number one reason to be in business (gasp). I know of a great building company that started as a people-centric organisation but has now lost its way. Culture erodes quickly when people and customer are secondary to profit making activities. If you focus on the people and process, the profits will come - 3Ps :-)

Implementing Lean in Construction

Ultimately the problem stems from the leadership focusing on profit and themselves, forgetting why the business exists in the first place. Take your mind off the numbers, focus on your customer, your people and serving others, and you'll be surprised how everything else will work out. Lean thinking is not about slashing operating expenses or people. It's about finding waste in everything that you do and constantly improving that process, optimising it, then optimising it again and again and again in a process of constant improvement. Ask your staff and your clients "what do you think about what you're/we're doing? What can we do better? Where can we improve? This is the easiest way for you to keep focused on improving and eliminating waste. Go ahead try it today.

The Role of Leadership

When you find ways to optimise your internal workflows and processes, you'll begin eliminating wasted labour costs, improving your product quality.

To effectively integrate lean thinking into your business, the process is critical. Here's a step-by-step approach to optimising your workflows:

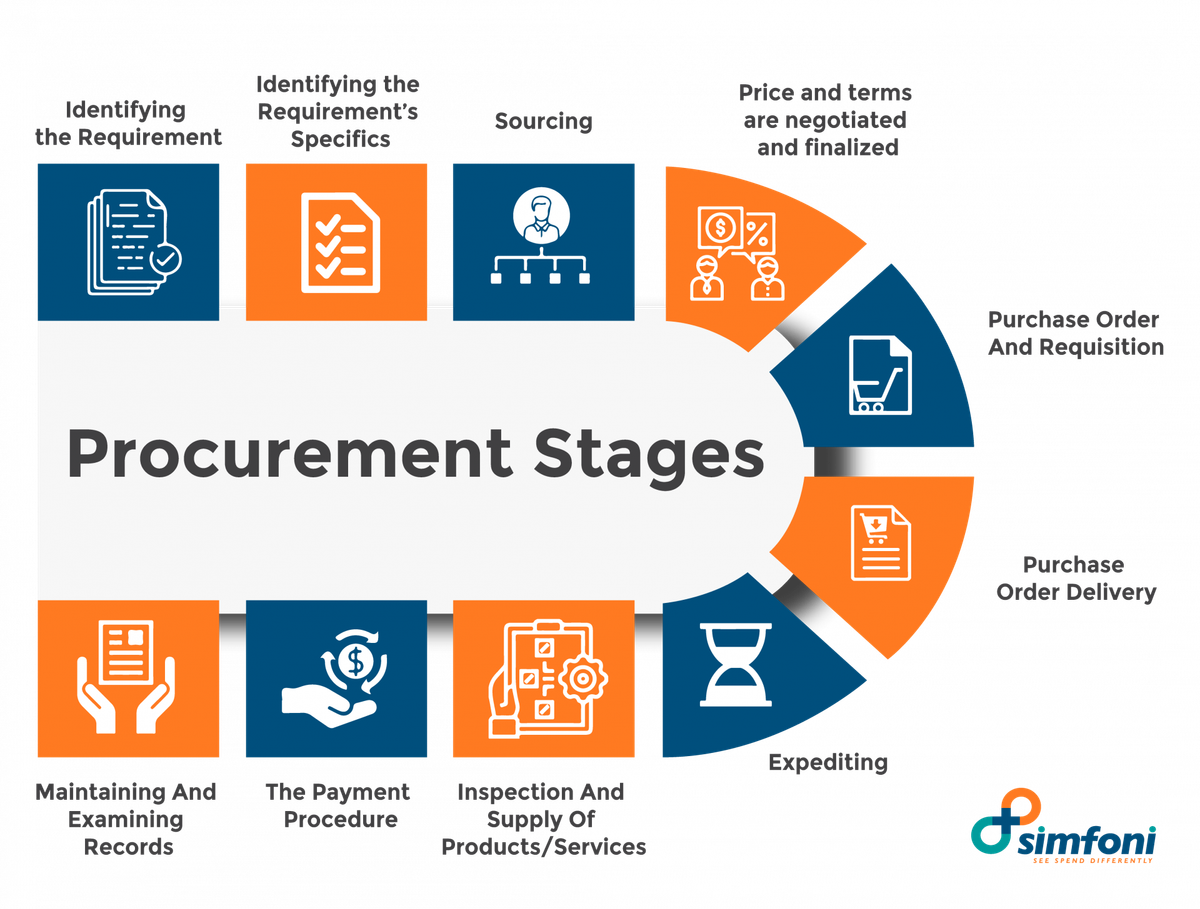

- Identify Value: Start by defining what value means to your customers. This involves understanding their needs and expectations. Engage with your customers directly through surveys, feedback forms, and conversations to get a clear picture of what they value most in your services and products.

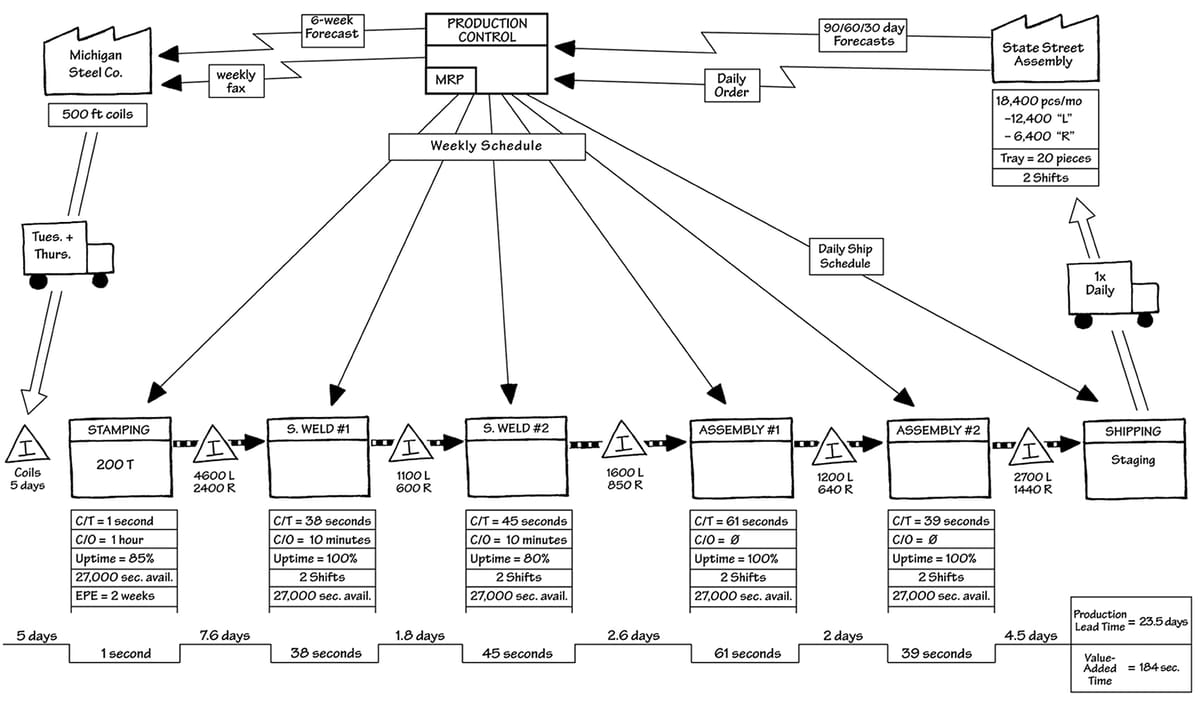

- Map the Value Stream: Once you know what your customers value, map out your entire process from start to finish. This value stream map should include every step involved in delivering your product or service, from raw materials to the final customer hand off. Identify all activities and categorise them into value-added and non-value-added.

- Eliminate Waste: Analyse the value stream map to identify and eliminate waste. Waste can take many forms: unnecessary movements, excess inventory, waiting times, overproduction, defects, and more. Focus on removing these inefficiencies to streamline your process.

- Create Flow: Ensure that the steps in your process flow smoothly from one to the next without interruptions. This might involve reorganising workspaces, aligning tasks more effectively, or automating repetitive tasks. The goal is to create a seamless workflow that minimises delays and bottlenecks.

- Implement Pull Systems: Instead of pushing products or services through the process based on forecasted demand, use pull systems. This means that work is initiated by actual customer demand, reducing overproduction and inventory costs. Tools like Kanban boards can be very effective in visualising and managing this flow.

- Pursue Perfection: Lean is a continuous improvement methodology. Regularly review and refine your processes. Use metrics and key performance indicators (KPIs) to measure your progress and identify areas for further improvement. Encourage a culture where employees are empowered to suggest and implement improvements.

- Engage and Train Your Team: Your team is your greatest asset in implementing lean processes. Provide them with the necessary training and tools to understand and apply lean principles. Foster a culture of open communication where everyone feels responsible for the process and its improvements.

- Use Lean Tools: Utilise various lean tools and techniques such as 5S (Sort, Set in order, Shine, Standardise, Sustain), Six Sigma, Kaizen (continuous improvement), and root cause analysis. These tools can help you systematically approach and solve problems, ensuring that improvements are sustainable.

The Synergy of People and Process

By embracing lean thinking, you create a powerful synergy between people and process that ultimately defines and reinforces your purpose. When you prioritise your people—both customers and employees—you build a strong foundation of trust, engagement, and loyalty.

This human-centric approach ensures that every process improvement directly contributes to enhancing their experience and satisfaction. As your team members see the tangible benefits of their efforts, they become more motivated and aligned with the company's goals.

This alignment fosters a deeper sense of purpose, driving everyone to continuously seek ways to deliver exceptional value. In turn, a well-optimised process ensures that this value is delivered efficiently and effectively, reinforcing the company's mission to improve the quality of life for its customers. Together, people and process create a virtuous cycle that strengthens your purpose, differentiates your business, and paves the way for sustainable success.

Conclusion

Adopting lean thinking in the construction industry can set your business apart from the competition by consistently delivering high value to your customers. By focusing on purpose, people, and process, you can foster a culture of continuous improvement that enhances both customer satisfaction and employee engagement.

Remember, lean is not a one-time project but a long-term strategy that requires dedication and persistence. Start small, maintain momentum, and watch as these incremental changes lead to significant improvements in your business performance.

By eliminating waste and optimising your processes, you'll not only increase profitability but also create a more efficient, innovative, and customer-centric organisation. Keep asking, keep improving, and let lean thinking drive your success.