Welcome to a deep dive into the fascinating world of process management through the lens of the Theory of Constraints (TOC), a concept revolutionised by Eli Goldratt. This journey isn’t just for the seasoned project manager or process analyst. It’s for anyone intrigued by the challenge of making things better, faster, and more efficient – especially in the dynamic world of residential construction.

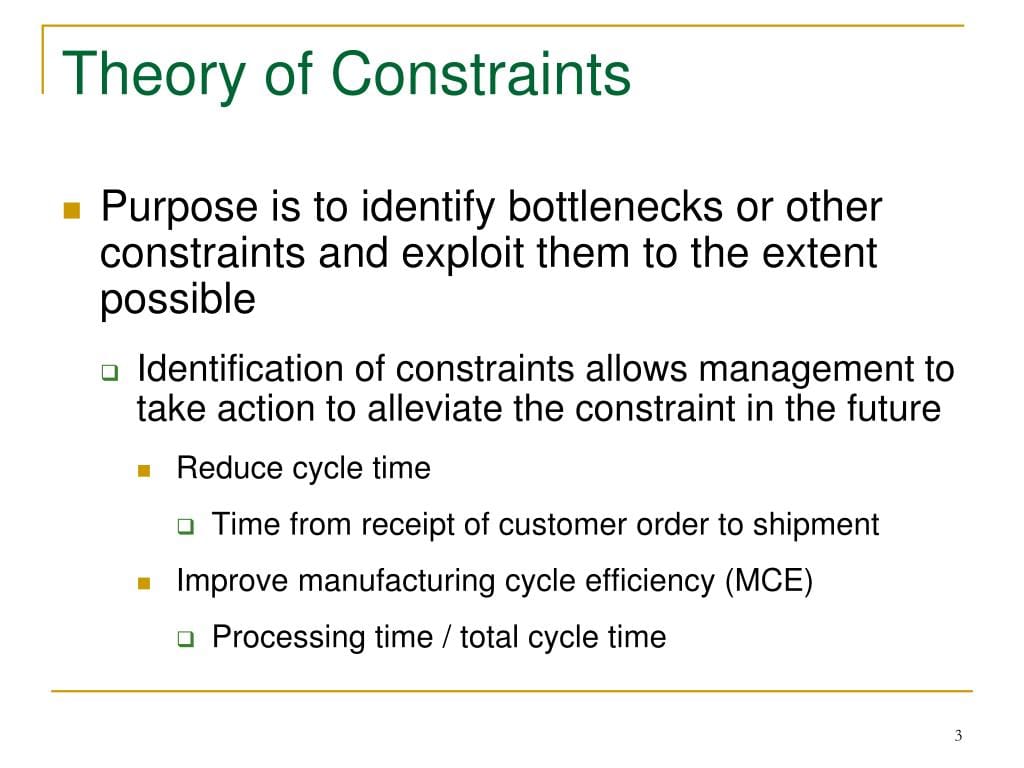

So, what exactly is the Theory of Constraints? Picture a chain. It’s only as strong as its weakest link, right? TOC applies this principle to business processes. It’s all about identifying the most critical limiting factor (i.e., constraint) in a process and systematically improving it. It’s not just a theory; it’s a practical, powerful toolkit for making real-world improvements.

How Does TOC Work?

TOC works in a surprisingly straightforward way. Imagine you’re navigating a busy highway. Your journey’s efficiency is limited by the slowest part – maybe it’s the traffic snarl at the bridge. In process terms, that’s your constraint. TOC is like finding a better route or perhaps improving the flow of traffic over that bridge. It involves several steps:

- Identify the constraints.

- Exploit the constraints (make the most of what you have).

- Subordinate everything else to the above decision (align all other processes).

- Elevate the constraint (improve or remove it).

- If, in the previous steps, the constraint has shifted, go back to step 1.

Applying TOC in Residential Construction

In residential construction, constraints could be anything from supply chain delays to skilled labor shortages. Let’s say the delivery of roofing materials is your bottleneck. TOC would guide you to first maximize the use of available materials, then adjust other work schedules around this constraint, and finally, work to improve or eliminate the bottleneck, perhaps by finding alternative suppliers.

Why is TOC Beneficial for Process Management?

- Focus: TOC hones in on the most impactful problems.

- Efficiency: By tackling bottlenecks, processes flow more smoothly.

- Continuous Improvement: It’s an ongoing cycle of improvement.

Theory of Constraints vs. Traditional Process Management

Traditional process management often tries to optimize every part of a process. TOC argues that this is a waste of time and resources. Why? Because improving a non-constraint doesn’t significantly impact the overall process. It’s like trying to clean a window with a dirty cloth; you’re not really addressing the root problem.

Value Stream Mapping: The Perfect Companion to TOC

Value Stream Mapping (VSM) is like a treasure map that shows you where to dig for efficiency gold in your process. It’s a visual tool that lays out all the steps in a process and identifies where value is added – and where it isn’t. Pairing VSM with TOC helps you see not just the bottlenecks, but also the impact of improving them on the entire value stream.

Practical Implications in Residential Construction

Consider a residential construction project. VSM might show you a map of the construction process, from foundation to finishing touches. TOC then steps in to identify where the real bottlenecks are. Maybe it's in the inspection phase. Focusing on improving or streamlining inspections can have a ripple effect that speeds up the entire project.

Simplifying the Complex: Metaphors and Analogies

Think of TOC in construction like a traffic light system in a busy city. If one light is out of sync, it causes delays not just at that intersection but throughout the city. TOC helps to keep all the lights green as much as possible.

Rhetorical Questions for Thought

- What if we could pinpoint the exact step where most construction delays happen?

- How much more could we achieve if we focused our energies on the real bottlenecks?

Conclusion: A World of Improved Efficiency Awaits

In the end, TOC isn’t just a theory; it’s a mindset. It’s about constantly asking, “What’s holding us back?” and “How can we do this better?” In residential construction, where every delay can cost time and money, applying TOC could mean the difference between a project that’s on time and budget and one that’s not.

For those new to process management or TOC, the journey might seem daunting at first. But remember, every step towards identifying and addressing constraints is a step towards greater efficiency and success. Whether you’re a project manager, a site supervisor, or just someone interested in the mechanics of efficiency, embracing the Theory of Constraints could be your first step towards transforming the way you work.